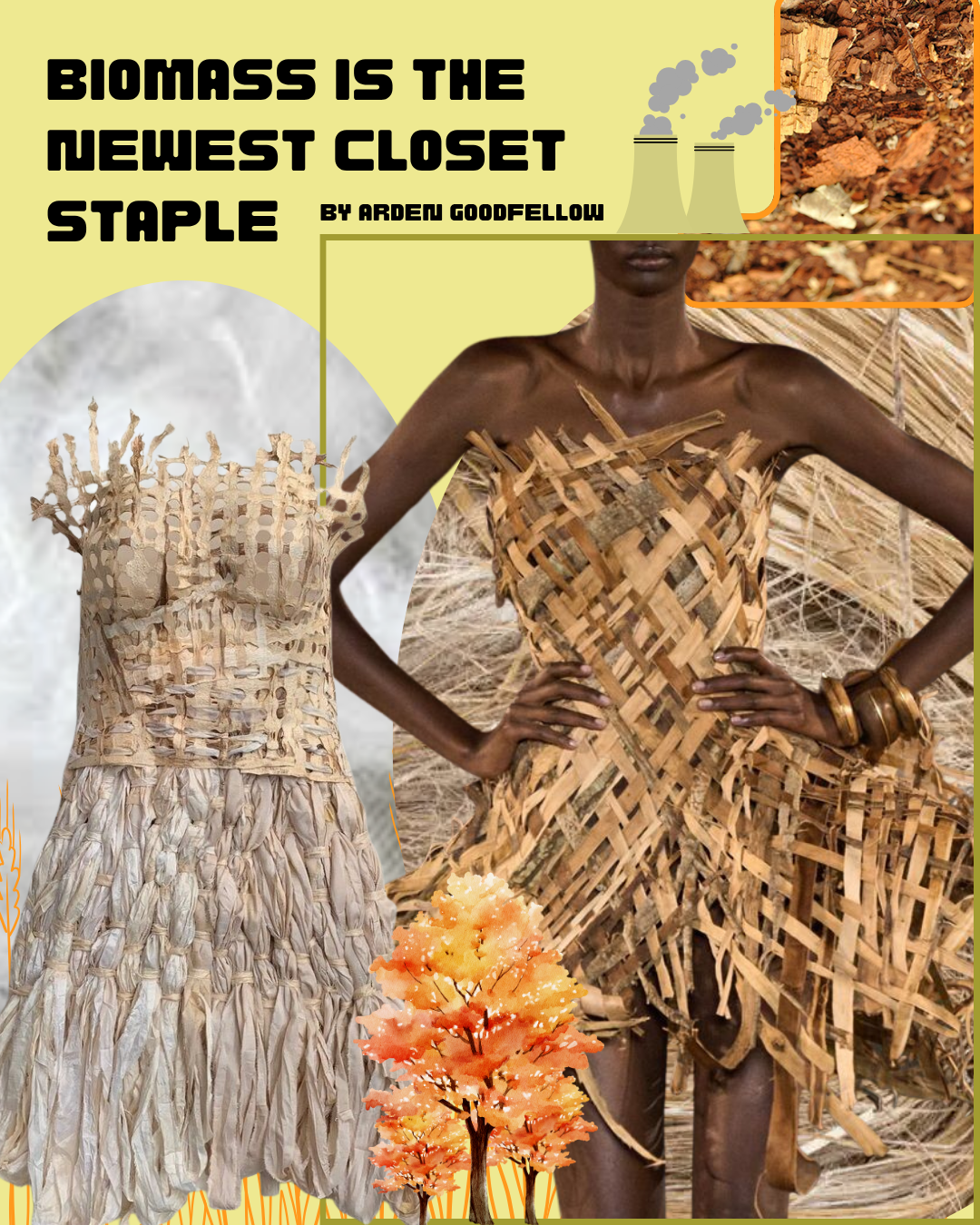

Biomass is the newest closet staple

09/30/2025

Written by Arden Goodfellow

Did you know that your sweater could be made out of biomass? Biomass is made of recently living organisms' matter, most commonly reused as a source for energy production. Examples of biomass include wood, wood residues, crops, agricultural residues, and organic waste from industrial and household sources. The most prevalent form of biomass today is wood and wood residues such as pulp. The majority of biomass waste is left in fields to naturally decompose, discarded in landfills, or incinerated. None of these methods is necessarily efficient, and they are also responsible for a great deal of environmental pollution, such as greenhouse gas emissions and effluent release.

Every year, over 50 billion tons of land-based biomass are produced, 99.9% of which is plant-based. This provides scientists with an opportunity to harness this waste and provide it with a second life.

So what if I told you that these organic waste forms could be another step towards sustainable clothing and promoting a circular economy? The most common materials used for textile production are cotton, wool, leather, polyester, nylon, and acrylic. The natural fibres of cotton, wool, and leather are obtained from plants and animals; for example, cotton comes from cotton plants and silk comes from silkworms. It is predicted that due to the shortage of food crops and increased use of biofuels, cotton cultivation will be replaced by other grains in the near future, leading to a possible shortage of cotton globally.

With the constant demand for clothes, another issue is that companies and manufacturers are more interested in the timely production of materials. This is why synthetic fibres are becoming more and more popular. Synthetic fibres are made completely by man, often from petroleum or coal-based polymers. As resources of raw, organic textile materials continue to diminish, using biomass fibres will prove to be an important step in expanding the market of sustainable textiles.

An example of this is banana fibres. Banana cultivation is done around four times a year. Following the harvest, the stems of the bananas were left to decompose, but now these stems can be recycled, and fibrous material can be extracted from them. BANANA TEX is a company harvesting banana fibres out of the Philippines to manufacture the first durable, technical fabric made purely from the Abacá banana plants. The company's manufacturing plant is completely self-sufficient, and requires no pesticides, fertilizer or extra water use. Banana fibre is a completely circular alternative to the synthetic fabrics that dominate the clothing market today. Approximately 100 million tons of bananas are cultivated each year across the globe. If these resources are appropriately utilized, the fibrous material obtained from them would be equivalent to over 30 million tons of cotton.

Another example of this is DuPont’s Sorona material. It is an eco-efficient fibre made in part from renewable plant-based ingredients. The first step is to harvest crops and then extract sugar or glucose from them. Microorganisms are then added to the glucose to start the fermentation process. Fermentation replaces the need for chemical synthesis, which produces PDO (1,3-Propanediol) in a natural way. TPA (terephthalic acid) is added to the Bio-PDO, creating a molecular bond and forming the fibre material. In comparison to nylon, this material uses 30% less energy and releases 63% fewer greenhouse gas emissions.

Both BANANATEX and DuPont are taking extraordinary leaps in sustainable clothing. By enhancing biomass waste into usable materials for clothing and other textiles, it will be able to significantly combat the GHG emissions and pollution created by the current, harmful textile industry.

Biomass is quickly becoming more than just a harvest waste; it is becoming a closet staple.